The inspiration behind the RoboCraftsman: Create a rapidly deployable manufacturing platform designed to help the Department of Defense produce sheet metal parts on demand.

It’s all about fixing planes quickly, answering the DOD’s need for high-mix, low-volume sheet metal part production.

“When an aircraft is grounded waiting for a replacement part, it’s not just a logistics issue — it’s a readiness issue,” said Edward Mehr, chief executive and co-founder of Machina Labs. “At Machina Labs, we’re enabling the U.S. military to manufacture mission-critical parts on demand, as close to the point of need as possible. This contract demonstrates the DOD’s confidence in our technology and its commitment to advancing agile, AI-driven manufacturing across sustainment operations.”

“UDRI is happy to partner with Machina Labs and the Air Force as we work together to develop, validate and qualify their RoboCraftsman integrated sheet metal forming equipment, designed and built by Machina,” said Brian Stitt, division head for sustainment technologies at the University of Dayton Research Institute.

UDRI is one of the Dayton area’s biggest and busiest defense contractors.

Engineers and technicians are working through early qualification of the equipment in order to validate the first several sheet metal parts a customer will use, Stitt said.

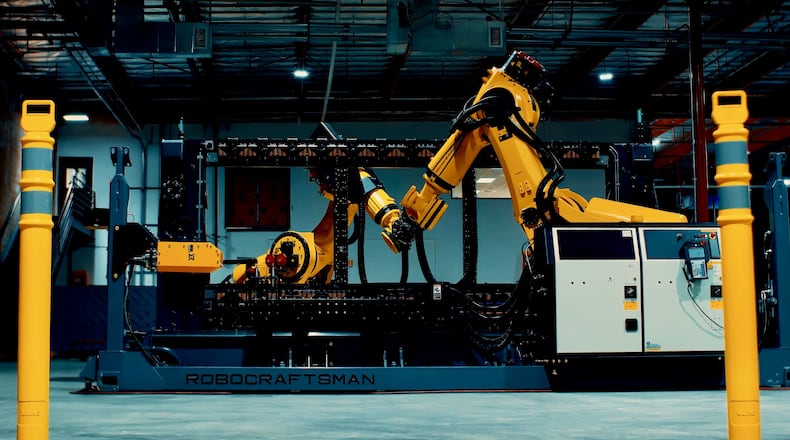

Equipped with two 7-axis robotic arms, a tool-changing system, and AI-driven process controls, the machine’s home will be the University of Dayton’s new Integrated Technology Operations Center facility in Kettering.

The platform includes Machina Labs’ proprietary forming technology, along with scanning, trimming, and drilling functions, the company said in an announcement.

It will be deployed to UDRI in a team effort with the Air Force Rapid Sustainment Office to help the service train, identify and qualify replacement parts for multiple aircraft.

RoboCraftsman eliminates the need for traditional dies and expensive physical tooling, allowing for the fast production of complex sheet metal parts, Machina Labs said.

This capability helps address delays and costs faced by Air Force depots in sourcing or manufacturing components, the company said.

The RoboCraftsman can form sheet metal parts from a wide range of materials, including steels, aluminum alloys, titanium alloys, and nickel-based superalloys.

Its compact, modular design allows for deployment in less than a day, enabling manufacturing on the go at military depots or in forward-deployed locations, Machina Labs said.

About the Author